For ALPMA, sustainability means acting responsibly for current and future generations. At the same time, we are also creating the conditions for sustainable, long-term corporate success. On the way there, we have committed ourselves to a concrete roadmap. It is linked to requirements and intermediate stops, which we continuously pursue. You can find an overview of our activities here:

ALPMA is closely rooted in Bavaria and its region. We feel committed to the people, tradition and social responsibility here in the surrounding area.

Our close relationship with the region is not only underlined by the investments in our location and support for our employees - it is also reflected in our local social commitment. This is "a real affair of the heart for us", as Mr Hain (left) and Mr Blattenberger (right), both shareholders and members of the ALPMA family advisory board, emphasise. "We find optimal conditions for ALPMA here in the region south of Munich, and we are truly grateful for that." That's why it's important for us to give something back - among other things by specifically supporting social institutions in the area (e.g. Schellensau e. V., Rotter Tafel e. V., Ronald McDonald Haus-Vogtareuth) and also sponsoring regional clubs (such as ASV Basketball Rott and TSV Wasserburg).

ALPMA's successful growth curve is largely based on our highly motivated and qualified workforce - today at 50 locations in 39 countries.

ALPMA offers a diverse and challenging working environment with sustainable perspectives in combination with a very special culture of a global family business. Our long-standing employees are a decisive factor in ALPMA's success. We are pleased when employees are connected to us within their own family over generations - a rare fact these days.

More sustainability can also be achieved through adjustments to working conditions. The ALPMA employees have the possibility to work in a home office.

In addition to personal benefits, we generate environmental benefits, such as Co2 savings through:

Bees make an important contribution to the preservation of our ecosystem, as together with other insects they are responsible for the pollination of our plant world and …

ensure its continued existence and diversity. For this reason, bees are of elementary importance to the

One of our claims sums it up with a twinkle in the eye: "Behind every good cheese is nature - and often ALPMA".

As the world's leading family-owned company in the field of mechanical engineering for the cheese and food industry, we are aware of our responsibility towards mankind and nature and offer bees a habitat in the area of our car parks. They find ideal conditions in the adjacent meadows and forests.

Cycling has been proven to have many positive effects on health and contributes significantly to environmental and climate protection.

Exhaust fumes, traffic jams, noise and over-parked areas are a huge burden on the environment and climate. In some German cities, driving restrictions are in place because limit values for air pollution such as nitrogen dioxide are permanently exceeded. Bicycles are emission-free, cause neither traffic jams nor noise and save space. With the job bike offer, ALPMA encourages every employee who can to come to work without a car.

We take care to avoid waste in our production processes, including auxiliary and operating materials, or, where this is not possible, to recycle them.

All current laws, regulations and codes of conduct are observed and integrated into our management systems. We control our emissions, ensure proper waste water treatment and dispose of waste and hazardous substances in a professional manner. (e.g. paper and wood by Zosseder, and acids and alkalis by GSB Bayern). By disposing of waste in a professional manner, we reduce or avoid harmful environmental impacts. Recycling protects our environment and thus contributes to preserving the basis of life for all living creatures and a functioning natural balance.

Our French subsidiary Servi Doryl designs and manufactures a wide range of cheese moulds and ripening solutions for numerous cheeses worldwide.

Here, too, the group is keen to adopt a sustainable approach and minimize the negative impact on the environment. Thus, all products of the mould manufacturer, which are made of plastic or metal, are designed for a long service life. Products made of metal, stainless steel or aluminium are easy to recycle. Plastic from the moulds can also be regenerated and reused. Thus, the polypropylene of plastic moulds can be found in numerous building materials or automotive applications. A service that more and more customers are now taking advantage of.

We find: Good Ideas should be kept up.

Here at the "Rott am Inn" site, we use 100% renewable energy from the region and are thus taking a significant step towards a climate-neutral future.

The green electricity for ALPMA at "Rott am Inn" comes from "Rosenheim", about 15 km away - from the "Rosenheim Landwerk". The "Landwerk", which belongs to the "Rosenheim" public utility company, markets electricity from small biogas plants, among other things. ALPMA actively supports green (renewable) energy.

Our goal is to continuously reduce energy consumption through greater energy efficiency. We have succeeded in doing this in Rott am Inn with a reduction in consumption of around 20% (2020 compared to 2016).

The goal is to further expand electricity self-production in order to become even more independent of the energy markets.

Through photovoltaic systems installed on the roofs of the assembly hall and the administration building in Rott am Inn, we want to produce our own electricity as much as possible in the future.

The goal is to further expand electricity self-production in order to become even more independent of the energy markets.

Continuous curd preparation with ALPMA coagulator and bassine system enables a higher cheese yield compared to classic cheese vats.

Due to shorter downtimes and careful curd preparation in smaller quantities, less curd fines are produced in the whey. More cheese is produced from less milk.

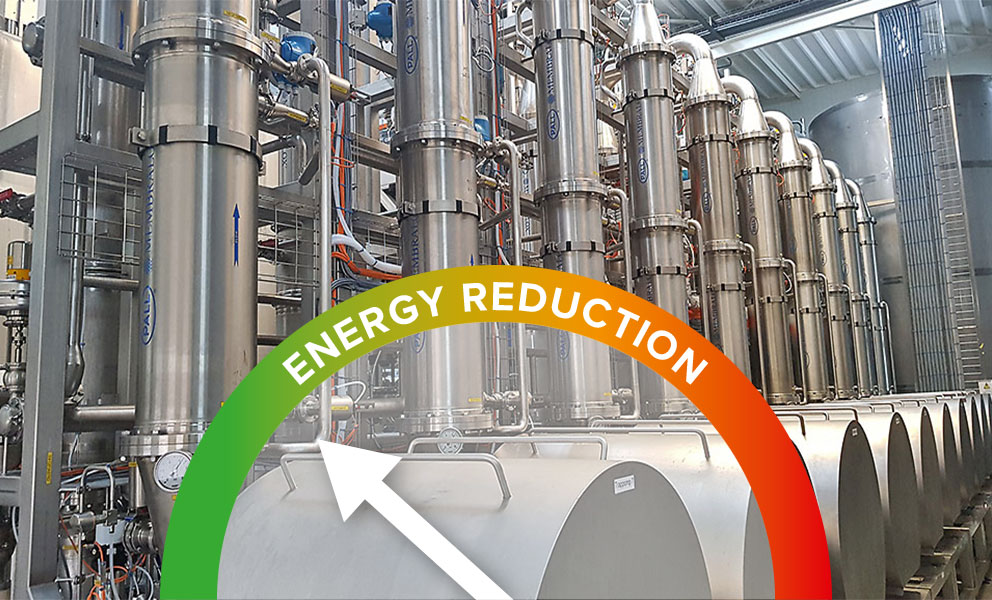

By draining the cheese in ALPMA climate tunnels at specific climatic conditions (temperature and humidity), energy consumption is decisively reduced compared to the energy consumption for air conditioning the entire premises.

All the whey produced on the equipment and transport systems is completely collected and processed. This also relieves the drainage water systems and sewage treatment plants.

ALPMA hardware and software solutions ensure high functionality of the cheese-making technology. The machines, sensors, software and real-time communication enable precise monitoring of the entire plant. Thus, timely preventive maintenance of the entire plant technology is planned and carried out and the longevity of the plant technology is guaranteed.

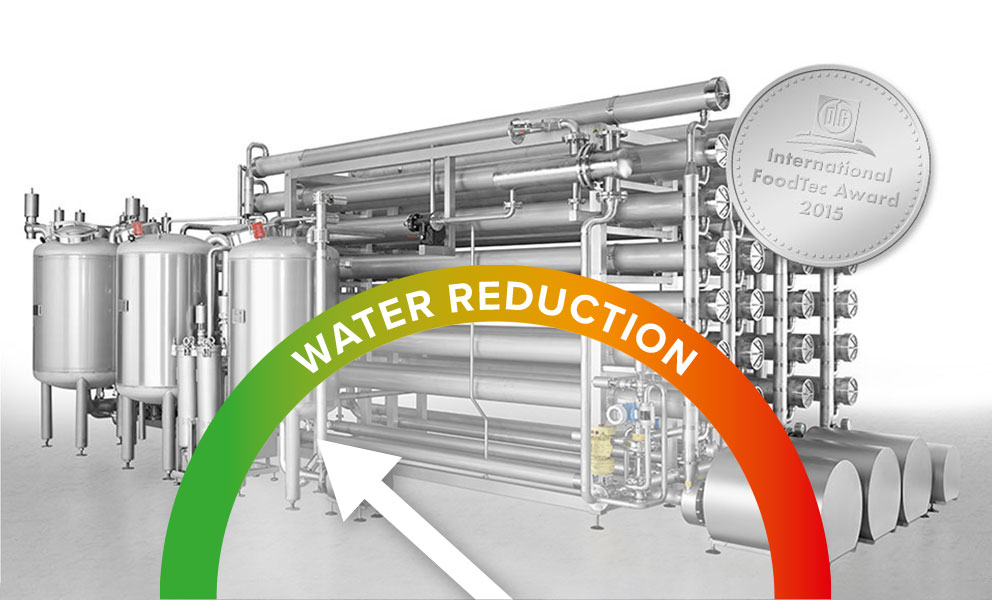

ALPMA has developed the AquaECON system together with HORPOVEL®. We can use it to reduce the amount of water needed to clean an RO plant by 20% to 35%.

Our engineers use precise measurements to ensure that the cleaning is just as effective as with higher water consumption.

ALPMA has developed the Smart Rinsing System. It allows us to reduce the amount of water needed to clean a membrane filtration system by 20%.

Through clever combination and switching of valves, product- or detergent residues are removed from the plant without residues and with significantly less rinsing water.

With the System Excavation System, ALPMA increases the recovery of product at the end of each production cycle. Special valve circuits and adapted control of pumps

ensures a high proportion of usable product is obtained before the product residues have to be rinsed out.

By operating the pumps on membrane filtration plants at the lowest possible speed, the consumption of electrical energy is optimised.

Clever process monitoring ensures that it is always possible to see exactly what speed is required.

ALPMA already won the International FoodTec Award in 2015 for the innovation RO HighTS. Even then, ALPMA consistently focused on energy saving and ...

reduction of the CO₂ footprint. Our engineers have developed a membrane system for concentrating milk and whey that allows us to achieve a total solids content in whey of 30% and in skimmed milk of up to 36%. As a result, the number of tank trucks on the road can be reduced by up to 80%. ALPMA membrane technology enables significant energy savings compared to evaporation.

The DLG Food Technology Award stands for cutting-edge innovation, sustainability and efficiency (DLG – German Agricultural Society).

ALPMA Alpenland Maschinenbau GmbH from Rott am Inn has now been awarded the International FoodTec Award 2021 in Gold by the DLG (German Agricultural Society) and its specialist partners for its innovative "FreshPack" packaging concept - the world's first "butter packaging with freshness seal". Thanks to this innovative packaging concept, the use of plastic packaging for butter and mixed fats can be significantly minimised in the future, thus also reducing plastic waste.

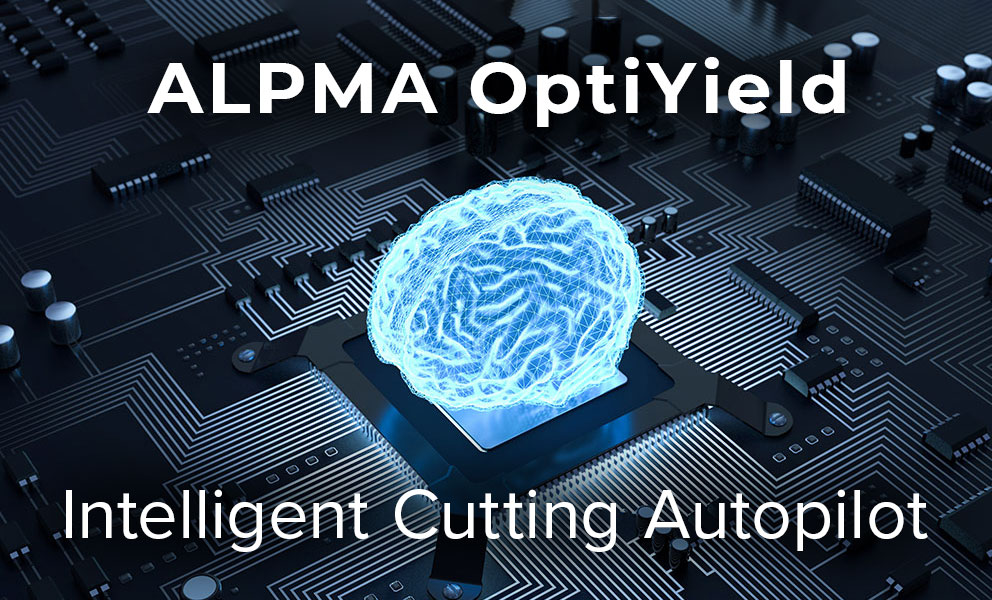

Digitalisation is playing an increasingly important role around the globe and will contribute enormously to the promotion of sustainability.

For example, the algorithm "OptiYield" developed by ALPMA ensures permanent monitoring of our cutting machines. OptiYield permanently learns from the data resulting from ongoing operation, evaluates the data in real time and continuously optimises itself. The settings, regardless of the model, are regulated independently to keep the performance at a permanently high level. These fast response times increase the efficiency of the slicers in terms of product utilisation, energy consumption and other aspects, and support the dairy's transition to more sustainable production.

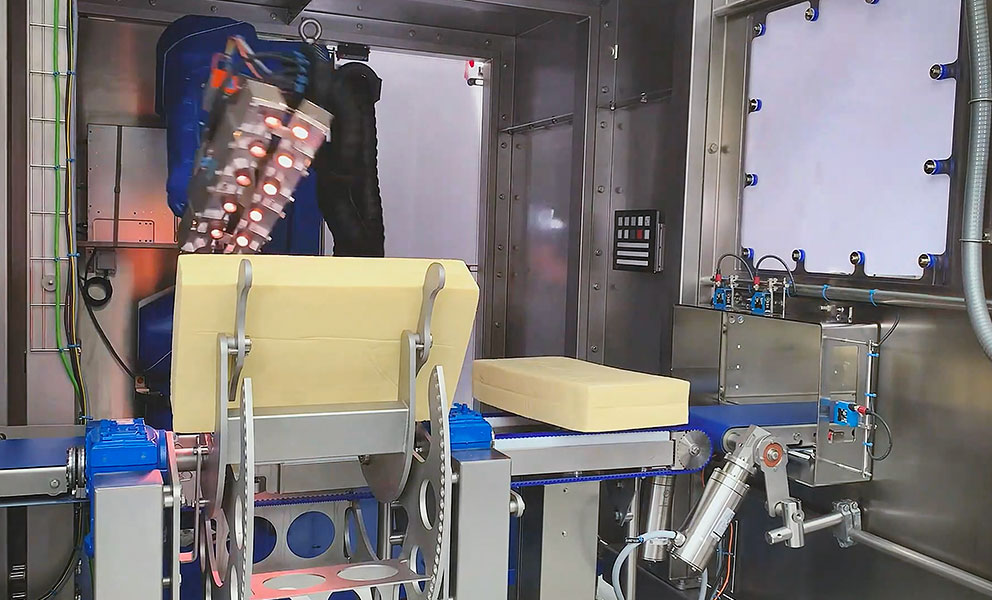

Automation solutions such as Eagle-Eye - ALPMA's innovative inspection technology with a hit rate of >99% - for production processes mean sustainability, ...

using resources more efficiently and relieving people of strenuous work. Furthermore, robots and customised automation solutions solve the challenges of cheese dairies, such as the growing shortage of skilled workers. With machines and matching software, ALPMA offers fully automated, customised solutions along the entire value chain for cheese dairies from a single source.

Durability is a crucial factor in using resources as efficiently as possible. The long service life of an ALPMA machine or its parts means long service intervals, ...

less downtime, higher efficiency and lower costs. In addition, we keep spare parts in stock for a long time. Thus, we help our customers with production reliability at a fast ROI.